Products

As a leader in the field of titanium, Osaka Titanium technologies will continue to fully explore the unlimited potential of this versatile materials.

Titanium

Titanium sponge

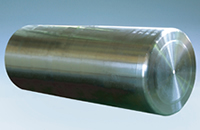

Titanium ingots

The current process for producing titanium was developed by Dr. Kroll in 1946. In 1952, our company became the first company in Japan to succeed in commercially manufacturing titanium and we are now among the world's largest makers of this product.

Titanium sponge is manufactured in six countries including Japan, the United States, Russia, Kazakhstan, Ukraine and China. However, only a few manufacturers, including our company, have the technology for manufacturing high-quality titanium sponge (referred to as premium grade) for use in the manufacture of critical parts such as aircraft engine components.

Due to our capability to develop unique technologies and our accumulated expertise, we are recognized by our customers as a leading manufacturer of titanium sponge, in terms of both quality and quantity.

We also manufacture titanium ingots using titanium sponge as the primary raw material. Distinctive features of our large titanium ingots include their excellent surface condition and high internal quality. Lightweight, strong and rustproof, our titanium ingots are processed into pipes and sheets; pipes for such large-scale facilities as thermal power plants, petrochemical and seawater desalination plants, and sheets for heat exchangers used in ships and LNG manufacturing plants. We intend to further expand our business based on the platform of titanium sponge manufacturing.

High-performance Materials

High-performance Materials with huge potential. We believe that one of our key responsibilities is to exploit their full potential and develop new products which meet our customers' needs. Accordingly, we intend to focus on fostering the high-performance materials business as our company's a next generation business.

TILOP

High purity titanium

SiO (Silicon Monoxide)

Titanium powder