Environmental Conservation

Conservation of the Water Environment

The pollution load of wastewater is reported in accordance with the Water Pollution Control Act, the Act on Special Measures concerning the Conservation of the Environment of the Seto Inland Sea and the Hyogo Prefectural Ordinance. Wastewater from each process at all OTC production sites is treated using appropriate purification methods and discharged to public waters (rivers) and sewers.

The water management plan aims to "maintain the recycling rate of water (circulating cooling water) at 90% or more" at OTC's Head Quarters/Amagasaki Plant and Kishiwada Works as part of OTC's approach to resource circulation. The goal for FY2020-2022 has been achieved.

Please note that none of the company's production sites are located in areas of high water risk, as identified by the World Resources Institute's (WRI) WRI Aqueduct.

Number of violations of laws, regulations and ordinances related to water in 2022: 0.

Water intake, recycling rate and drained water data over the past 3 years

*1: The main sources of clean water and industrial water are rivers.

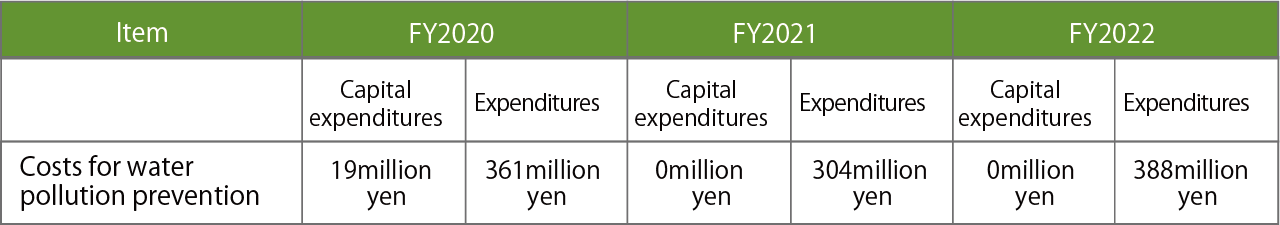

Costs associated with water-related risks and investments to mitigate those risks

The following table shows the water pollution control costs used to prevent abnormal discharges and to inspect and maintain water treatment facilities.

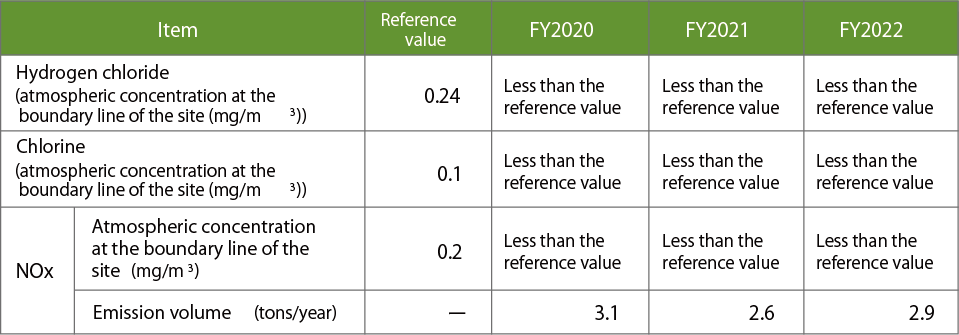

Conservation of the Atmospheric Environment

Control of soot and smoke reported under the Air Pollution Control Act and Hyogo Prefectural Ordinance. Emissions from each process at all OTC production sites are treated and discharged using appropriate treatment methods.

*There are no specific facilities emitting sulphur oxide (SOx) or volatile organic compounds (VOC) at OTC production sites.

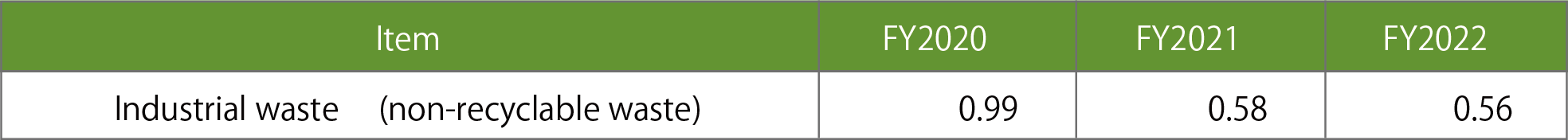

Waste Management

Appropriate resource procurement is carried out to prevent resource depletion, and appropriate management is carried out to reduce the environmental impact of waste after use.

Waste management intensity

Industrial waste intensity = Industrial waste (tons)*1/Production quantity closely related to energy consumption (tons)*2

*1 Value registered under the Wastes Disposal and Public Cleansing Act

*2 Value registered under the Energy Saving Act

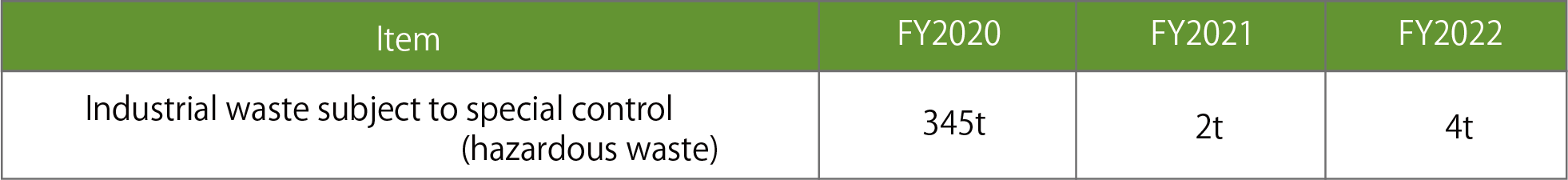

Waste subject to special control

Conducting Periodic Inspections

OTC verifies that industrial waste undergoes proper disposal by systematically conducting periodic audits to "confirm the on-site circumstances of waste disposal contractors" in line with its obligations to make efforts under the Wastes Disposal and Public Cleansing Act.

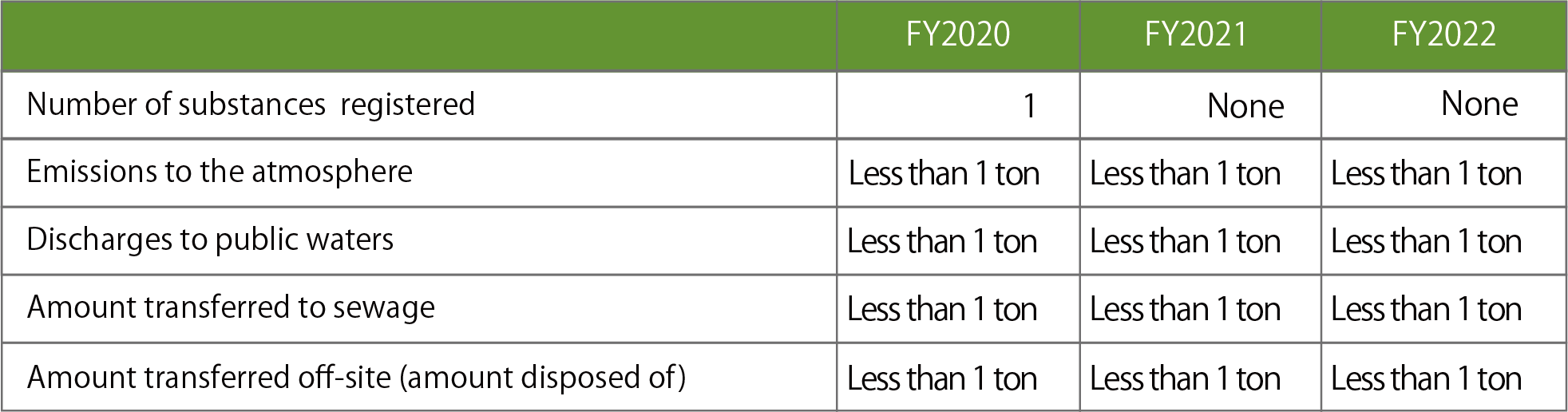

Management of Chemical Substances

As to the chemical substances covered by the for chemical substances related to the PRTR Act*1 and the Chemical Substances Control Act*2, OTC monitors their use, emissions and transfers, and works on activities to reduce their use and control their emissions. In addition, waste PCB electrical equipment and equipment using CFCs are properly stored and managed in accordance with the PCB Special Measures Law*3 and the CFC Emission Control Law*4 respectively.

*1

PRTR Act (Pollutant Release and Transfer Register), i.e., "Act on the Assessment of Releases of Specified Chemical Substances in the Environment and the Promotion of Management Improvement"

*2

"Act on the Regulation of Manufacture and Evaluation of Chemical Substances"

*3

"Act on Special Measures Concerning Promotion of Proper Treatment of PCB Waste"

*4

"Act on Rational Use and Appropriate Management of Fluorocarbons"

Annual movements and emissions of PRTR-reportable substances in the last three years